Evolution of spent nuclear fuel in dry storage conditions for millennia and beyond

Given the temperature needed to anneal alpha-defects and to initiate helium thermal diffusion it can be expected that the fluorite type dioxides based on U and Pu will be able to accommodate in their structure a large part of the radiogenic helium that will be created but, while remaining crystalline, these materials will experience high stress levels, and it is expected that their overall microstructure will be perturbed by formation of these nano-sized gas bubbles (latest after 1 dpa, hence 1000 years of storage of standard LWR fuel) and extended alpha-damage defects (dislocation loops). Based on the results presented here, such bubbles are not expected to start forming in conventional spent fuel for several thousand years; however, in MOX fuels, they could begin forming within 1000 years. On the contrary it was observed that the alpha-damage evolves rapidly even at low alpha-doses. In time, these two effects could lead to micro-cracking and partial loss of integrity. Consequently, the pressure exerted by the loss of helium on the next confinement barrier should be considered in any modelling assessment of spent fuel storage performance.

http://www.sciencedirect.com/science/article/pii/S0022311514001822

Abstract

Significant amounts of spent uranium dioxide nuclear fuel are accumulating worldwide from decades of commercial nuclear power production. While such spent fuel is intended to be reprocessed or disposed in geologic repositories, out-of-reactor radiation damage from alpha decay can be detrimental to its structural stability. Here we report on an experimental study in which radiation damage in plutonium dioxide, uranium dioxide samples doped with short-lived alpha-emitters and urano-thorianite minerals have been characterized by XRD, transmission electron microscopy, thermal desorption spectrometry and hardness measurements to assess the long-term stability of spent nuclear fuel to substantial alpha-decay doses. Defect accumulation is predicted to result in swelling of the atomic structure and decrease in fracture toughness; whereas, the accumulation of helium will produce bubbles that result in much larger gaseous-induced swelling that substantially increases the stresses in the constrained spent fuel. Based on these results, the radiation-ageing of highly-aged spent nuclear fuel over more than 10,000 years is predicted.

1. Introduction

Plutonium and minor actinides (americium, curium) constitute a small but very radiotoxic fraction of the elements produced in today’s widely used UO2 fuel but also in the mixed oxide (Ux, Pu1−x)O2 fuel (MOX) during the production of electricity from nuclear reactors. These elements pose the main problems for non-proliferation issues, spent fuel disposition (the spent fuel stored worldwide will amount ∼350,000 t of heavy metals in 2020 [1]), or for high level waste disposal in the countries where spent fuel is reprocessed (the reprocessed spent fuel will amount 120,000 t of heavy metals worldwide in 2020 [1]). Public acceptance of nuclear energy is strongly affected by the proposed solutions for these sensitive issues. Today’s strategy for the back end of the nuclear fuel cycle varies from one country to the other [2], [3] and [4]. However, whatever option will be chosen, i.e. reprocessing and recycling or direct disposal, potentially following interim storage, the nuclear waste will have to be safely stored for long periods of time.

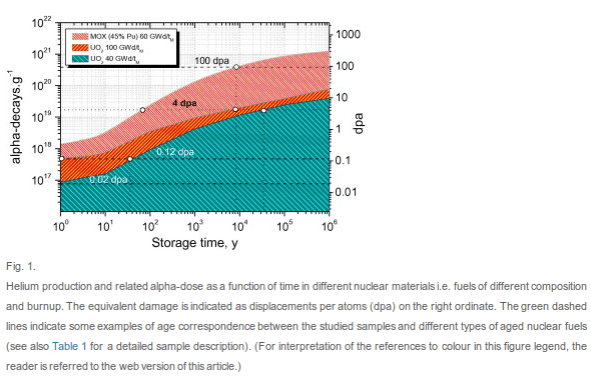

While nuclear fuel in reactor undergoes significant restructuring due to the radiation effects from fission and to high operating temperatures [5], the radiation and temperature environment for spent fuel out of reactor is substantially different. After decay of the predominantly beta-decaying short-lived fission products, the spent fuel will be subjected primarily to alpha-decay self-radiation damage and radiogenic helium accumulation at near ambient conditions, where completely different atomic level processes will dominate for millions of years. Fig. 1 shows as an example the alpha-dose evolution, hence helium production, during time for different types of nuclear fuels. Thus, the spent nuclear fuel available and characterized today is not representative of the structure and state of aged fuel after hundreds or thousands years of storage because it has not yet experienced a significantly long accumulation of microstructural defects and of helium due to alpha-decay [6].

Because of the handling, transport and storage of spent fuel, it is of critical importance to study the aging of these materials in order to predict their long term behaviour and risk to the biosphere. The goal is to understand and assess the processes responsible for the alteration of materials subject to radiation damage in view of their long term integrity. The foremost alteration process is associated with the build-up of radiogenic helium and alpha-damage that could cause early material degradation and enhanced corrosion [7], [8], [9], [10], [11] and [12]. Whether the fuel can or cannot retain the helium is of prime importance in assessing its long term mechanical stability. An increase of about 20 bars, in addition to the 25 bars of helium present at the beginning of irradiation, has to be accounted for in the fuel rod after a typical irradiation of a UO2 fuel at a standard burnup. About 55% of this pressure increase is due to swelling of the fuel and consequent decrease of the free volume. If helium is generated during storage and not retained in the fuel, it will increase further the pressure. If disintegration of the fuel pellet occurs, additional gas will be released to the free volume from the opening of pressurized bubbles with a small compensation from the pores to the overall new free volume. This aspect would be more critical for fuel containing more shorter living actinides, as is the case for example for MOX fuel which in turn will produce more helium during storage (see Fig. 1). As a matter of fact, the cladding, which constitutes in some operational approaches the first confinement barrier after the fuel pellet in case of interim or long term storage, and should withstand over-pressurisation due to the production of helium in case it is released because of fuel embrittlement. For example, the production of 1020 He g−1 in a MOX (burn-up 40 GWd t−1) fuel after 10,000 years would result in an increase of 50 bar of total pressure if one assumes a free volume of ∼20 cm3 in a cladding tube and a total release of He from the spent fuel pellet.

Increases in lattice parameter induced by the accumulation of gas and of defects from alpha-decay might cause swelling of the spent fuel and its early failure. Interactions between the radiogenic helium formation and the defects produced by alpha-particles and recoil nuclei need to be understood to predict the evolution of the system. Aged spent fuel is not available today it can only be simulated by accelerated aging of materials with a structure comparable to fuel or by studying natural analogues having cumulated high alpha-dose [7], [13], [14], [15] and [16].

After irradiation in a nuclear reactor the fuel has experienced about 4–5% of fissions and the formation of fission products (FP) that modify the chemical composition and microstructure of the fuel. However, part of the inventory of the FP is segregated from the UO2 matrix. The gases are typically precipitated into bubbles with sizes between nm and μm as function of their radial position (temperature during irradiation). The five metal particles mainly composed of Pd, Ru, Rh, Tc and Mo and have sizes ranging between nm and μm also depending on the irradiation temperature [17]. The residual activity dominated by beta and gamma decay generates a decay heat of 1 kW/t ten years after discharge while after 10,000 years the activity will be predominantly caused by alpha-decay generating a decay heat of about 20 W/t [18]. At discharge, in a LWR fuel with a burn-up of 40 GWd/t having a residual temperature of 500 K, the thermal conductivity has decreased by ∼50%, from 5.8 W m−1 K−1 as in fresh fuel to 3.0 W m−1 K−1[19]. The lower the temperature of the fuel the higher is the degradation of the thermal conductivity. However, since the total thermal power decreases with time, in wet storage conditions the fuel temperature will not exceed 473 K, which would even be the limit in dry storage conditions after a few decades [20]. For comparison our 238PuO2 sample (see Table 1) has a decay heat of 350 mW/g. The oxygen potential of the fuel is almost close to the one of stoichiometric fresh fuel even if locally there can be slightly sub-stoichiometric domains.

For more details, the full report can be found here;

http://www.sciencedirect.com/science/article/pii/S0022311514001822

Conclusion

Alpha-decay damage will be the dominating effect modifying the structure of spent nuclear fuel during long term storage. In order to predict spent fuel behaviour, radiation ageing of spent fuel has been studied using natural analogues and accelerated approaches with fuel surrogates doped with strong alpha-emitters. In this study, different alpha-damaged samples hence containing very different quantities of radiogenic helium and alpha-damage have been studied by different techniques to elucidate some of the main parameters governing the spent fuel evolution in storage/disposal condition. The investigation of alpha-damage by XRD, TEM and Vickers Hardness showed that the fluorite structure is preserved but with a substantial increase in lattice parameter (up to 0.6%), the formation of dislocation loops (4 × 1022 m−3), the formation of helium bubbles and an increase of the Vickers Hardness. Thermal desorption (TDS) studies and defect annealing studies showed that at the temperature expected for storage neither substantial recovery of defects nor diffusion of helium will occur. Given the temperature needed to anneal alpha-defects and to initiate helium thermal diffusion it can be expected that the fluorite type dioxides based on U and Pu will be able to accommodate in their structure a large part of the radiogenic helium that will be created but, while remaining crystalline, these materials will experience high stress levels, and it is expected that their overall microstructure will be perturbed by formation of these nano-sized gas bubbles (latest after 1 dpa, hence 1000 years of storage of standard LWR fuel) and extended alpha-damage defects (dislocation loops). Based on the results presented here, such bubbles are not expected to start forming in conventional spent fuel for several thousand years; however, in MOX fuels, they could begin forming within 1000 years. On the contrary it was observed that the alpha-damage evolves rapidly even at low alpha-doses. In time, these two effects could lead to micro-cracking and partial loss of integrity. Consequently, the pressure exerted by the loss of helium on the next confinement barrier should be considered in any modelling assessment of spent fuel storage performance.

The spent fuel composition and microstructure after discharge from the reactor would need to be considered in parallel to the findings obtained from this study of the ageing of the fuel matrix. Inhomogeneity in the spent fuel microstructure will certainly produce different effects and initial gas bubbles or pores distributed in the fuel will certainly allow accommodating a certain quantity of helium like for example the High Burnup Structure will do due to its inherent microstructure. It is accepted that the oxygen potential of the spent fuel will be buffered by the molybdenum. Also this aspect needs to be considered since the phenomena of damage and helium bubble formation modify the microstructure at a very small scale and hence very local deviation from the O/M ratio could have stochastic effect on diffusion, hardness or fracture toughness with consequences on mechanical behaviour.

No comments yet.

-

Archives

- March 2026 (76)

- February 2026 (268)

- January 2026 (308)

- December 2025 (358)

- November 2025 (359)

- October 2025 (376)

- September 2025 (258)

- August 2025 (319)

- July 2025 (230)

- June 2025 (348)

- May 2025 (261)

- April 2025 (305)

-

Categories

- 1

- 1 NUCLEAR ISSUES

- business and costs

- climate change

- culture and arts

- ENERGY

- environment

- health

- history

- indigenous issues

- Legal

- marketing of nuclear

- media

- opposition to nuclear

- PERSONAL STORIES

- politics

- politics international

- Religion and ethics

- safety

- secrets,lies and civil liberties

- spinbuster

- technology

- Uranium

- wastes

- weapons and war

- Women

- 2 WORLD

- ACTION

- AFRICA

- Atrocities

- AUSTRALIA

- Christina's notes

- Christina's themes

- culture and arts

- Events

- Fuk 2022

- Fuk 2023

- Fukushima 2017

- Fukushima 2018

- fukushima 2019

- Fukushima 2020

- Fukushima 2021

- general

- global warming

- Humour (God we need it)

- Nuclear

- RARE EARTHS

- Reference

- resources – print

- Resources -audiovicual

- Weekly Newsletter

- World

- World Nuclear

- YouTube

-

RSS

Entries RSS

Comments RSS

Leave a comment